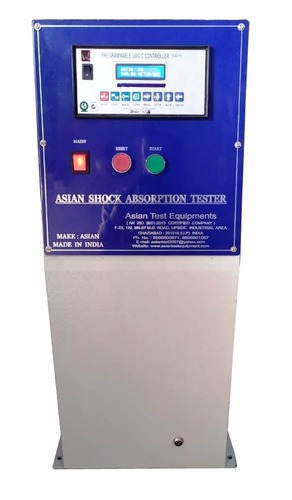

SHOCK ABSORPTION TESTER

Product Details:

- Interface Type RS232

- Specimen Size 50 300 mm

- Temperature 5C to 35C

- Measuring Range 0~20 kN

- Response Time <1 s

- Accuracy 0.5%

- Automation Grade Semi-Automatic

- Click to view more

X

SHOCK ABSORPTION TESTER Product Specifications

- Approx. 120 kg

- test range 10~90 Shore A

- 220 V

- 300 mm

- 0.5%

- Semi-Automatic

- 0.01 N

- 50 Hz

- Bench-top

- <1 s

- 0~20 kN

- 250 mm

- RS232

- 50 300 mm

- 5C to 35C

- AC 220V 10%, 50Hz

- 20 kN

- 0~5000 N

- Digital control with touch panel

- 10% to 80% RH

- Shock Absorption Tester

- 1/4 inch

- Material Laboratory Testing

- 0.4-0.8 MPa

- 20-300 mm/min (adjustable)

- High accuracy, easy operation, programmable testing

- Used to test shock absorption performance of foam, rubber, and cushioning materials

- 900 mm

- 1-2

- LCD digital display

- USB and RS232

- Automatic and manual calibration supported

- Impact, drop, compression

- <65 dB during operation

- Stores up to 1,000 test results internally

- PC Software for data analysis and test reporting

- English/Chinese selectable

- Overload protection, emergency stop button

- High precision strain gauge

- 1000 Hz

- Powder-coated steel

- 250 W

- Sample holders, calibration weights, dust cover

- 7-inch color touch screen

- Plug-and-play with quick setup guide

Product Description

Discover the rare and trending SHOCK ABSORPTION TESTER, a formidable instrument engineered for praiseworthy performance in modern material laboratories. Crafted with a durable powder-coated steel frame, this customizable tester supports unassailable accuracy-achieving 0.5% with a high precision strain gauge load cell. Benefit from versatile test modes, a 7-inch color touch interface, and robust safety features including overload protection and emergency stop. With advanced PC software for data analysis, rapid setup, and noiseless operation, this semi-automatic tester sets new standards in reliable shock absorption testing, ensuring exceptional results every time.

Plant Application and Testing Methodology

The SHOCK ABSORPTION TESTER is widely adopted in manufacturing plants and R&D labs, especially for foam, rubber, and cushioning material assessment. Its application method involves programmable impact, drop, and compression tests on a controlled media, using digital automation for consistent results. Operators can instantly analyze and report data with the included PC software, making it a leading choice for both production and quality assurance processes where material resilience is paramount.

Supply Ability, Export Markets, and Packaging

Our SHOCK ABSORPTION TESTER is available for prompt dispatch, with efficient supply ability to meet global demand. We cater to major export markets including Asia, Europe, and the Americas, ensuring seamless transport services. Each unit is securely packaged with accessories and calibration tools, guaranteeing safe delivery upon every exchange. Customers are charged reasonably based on order volume, and comprehensive import/export documentation ensures a smooth transaction from manufacturer in India to your facility worldwide.

Plant Application and Testing Methodology

The SHOCK ABSORPTION TESTER is widely adopted in manufacturing plants and R&D labs, especially for foam, rubber, and cushioning material assessment. Its application method involves programmable impact, drop, and compression tests on a controlled media, using digital automation for consistent results. Operators can instantly analyze and report data with the included PC software, making it a leading choice for both production and quality assurance processes where material resilience is paramount.

Supply Ability, Export Markets, and Packaging

Our SHOCK ABSORPTION TESTER is available for prompt dispatch, with efficient supply ability to meet global demand. We cater to major export markets including Asia, Europe, and the Americas, ensuring seamless transport services. Each unit is securely packaged with accessories and calibration tools, guaranteeing safe delivery upon every exchange. Customers are charged reasonably based on order volume, and comprehensive import/export documentation ensures a smooth transaction from manufacturer in India to your facility worldwide.

FAQ's of SHOCK ABSORPTION TESTER:

Q: How is the SHOCK ABSORPTION TESTER operated and what safety features does it provide?

A: The tester is operated via a user-friendly 7-inch color touch screen and supports digital control with a quick plug-and-play setup. It includes safety features such as overload protection and an emergency stop button to ensure operator security during all testing procedures.Q: What applications and materials are suitable for this equipment?

A: It is ideal for testing shock absorption in foam, rubber, and cushioning materials, making it suitable for material laboratories, manufacturing quality control, and R&D environments focusing on material durability and performance.Q: When should I perform calibration on the SHOCK ABSORPTION TESTER?

A: Calibration can be performed both automatically and manually, as needed, to maintain the tester's precision. It is recommended to calibrate before critical testing sessions or after significant usage for consistent accuracy.Q: Where can the test results be stored and how is data output managed?

A: Test results are internally stored for up to 1,000 tests, and data can be easily output via USB or RS232 interfaces for integration with PC software, enabling advanced analysis and comprehensive test reporting.Q: What is the process for setting up the tester upon delivery?

A: Installation is streamlined with a plug-and-play design and a comprehensive setup guide. Simply unpack, connect to a suitable power supply, and use the touch panel to initiate your desired test sequence.Q: What are the benefits of using this tester for export-oriented manufacturing?

A: The tester's high accuracy, customizable testing parameters, and robust construction help exporters assure product quality, comply with international standards, and enhance customer satisfaction across multiple markets.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email