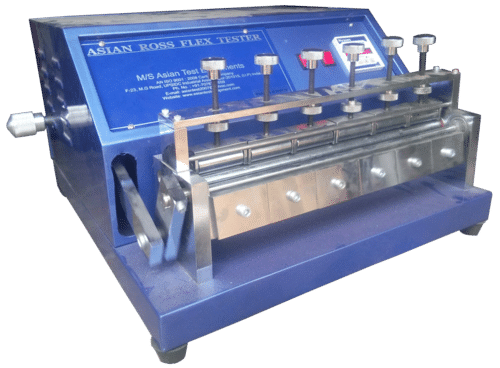

Rubber Compression Tester

Product Details:

- Measuring Range 025 mm

- Temperature Room Temperature to 150C

- Operating Voltage 220V

- Specimen Size 29 mm x 12.5 mm

- Power Supply 220V AC, 50Hz

- Frequency 50 Hz

- Number of Specimens Up to 3

- Click to view more

X

Rubber Compression Tester Product Specifications

- 025 mm

- Digital Control

- Room Temperature to 150C

- 220V

- 29 mm x 12.5 mm

- 50 Hz

- Up to 3

- 220V AC, 50Hz

- 40%95% RH

- Approx. 50 kg

- 0.01 mm

- 100 mm

- Digital Display

- Compression Tester

- Sturdy frame, Automatic reset, Safety Lock

- 10 kN

- Up to 7 bar

- Controlled, up to 500 mm/min

- < 1 s

- 0.01 mm

- Standard 6 mm

- Rubber Compression Set Testing

- 020 mm

- 500 mm

- Laboratory/Industrial

- Factory calibrated certificate included

- Emergency stop, Overload protection

- Manual lift screw

- Flat Platen

- Mild steel with powder coating

- Scratch and chemical resistant paint

- Digital & USB

- 550 mm x 350 mm x 600 mm

- ASTM D395 / ISO 815

Product Description

Since our rise in year 1994, we are manufacturing, exporting and supplying Rubber Compression Tester. At our well-equipped production unit, the offered tester is manufactured under the stern vigilance of our experts using optimum quality components with the help of latest techniques. This tester is specially designed for determining the compression strength of rubber. Apart from this, the offered Rubber Compression Tester can be purchased from us at the best market rates.Features:

- Easy to operate

- Low maintenance

- Long-service life

- Rugged design

Certified Precision and Compliance

Equipped with a factory calibration certificate, this compression tester strictly adheres to ASTM D395 and ISO 815 standards. Its high-precision digital control and automated reset functions ensure reliable and repeatable results for every test. The equipment measures compression set values with exceptional accuracy, supporting quality assurance processes for rubber materials.

Robust Build for Extended Use

Manufactured with mild steel and a powder-coated finish, the tester offers superior resistance to scratches and chemicals. Its sturdy frame, manual lift screw, and safety lock features boost operational longevity and user protection. Designed for easy installation in laboratories or industrial settings, its compact footprint saves workspace.

Advanced Data Handling and Flexible Operation

With digital and USB outputs, managing and storing test results becomes seamless. The device provides a controlled testing speed up to 500 mm/min and accommodates a wide temperature range, supporting diverse testing requirements. Its compatibility with up to three specimens at once enhances testing efficiency.

FAQs of Rubber Compression Tester:

Q: How is the calibration of the Rubber Compression Tester certified?

A: Each Rubber Compression Tester comes with a factory calibration certificate, guaranteeing that it meets ASTM D395 and ISO 815 standards. This assures users of test accuracy and traceability for quality control applications.Q: What safety features are integrated into this tester?

A: The tester is equipped with an emergency stop and overload protection system. Additionally, it includes a safety lock and a sturdy frame construction to provide secure and safe operation in both laboratory and industrial environments.Q: When should the test specimens be loaded and how is the process carried out?

A: Test specimens, with dimensions 29 mm x 12.5 mm, can be manually loaded using the lift screw mechanism. Up to three specimens can be loaded at a time, ensuring efficient throughput during routine quality assessment.Q: Where can this compression tester be installed?

A: Designed for both laboratory and industrial usage, the machines compact size (550 mm x 350 mm x 600 mm) allows for easy installation on standard workbenches or dedicated testing stations. Its scratch and chemical resistant finish further suits demanding environments.Q: What is the process for conducting a rubber compression test using this equipment?

A: The process involves placing the properly sized specimens under the flat platen indenter, manually adjusting the lift screw, and initiating the test via digital controls. The response time is less than one second, and test outcomes are displayed digitally and can be exported via USB.Q: How does the digital data output benefit laboratories and manufacturers?

A: Digital and USB data outputs simplify result recording, analysis, and archiving. This streamlines compliance documentation and quality verification, enhancing overall workflow and traceability.Q: What types of rubber materials can be tested with this equipment?

A: The tester is suitable for a wide range of rubber materials that require compression set evaluation under standard conditions. Its broad temperature and humidity operating ranges provide flexibility to test various rubber compounds as per international standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free