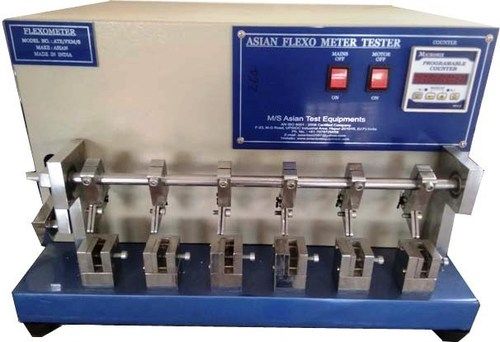

FLEXOMETER Tester

Product Details:

- Measuring Range 0 - 100,000 cycles

- Power Supply 220V AC, 50 Hz

- Resolution 1 cycle

- Accuracy 1 cycle

- Automation Grade Semi-Automatic

- Specimen Size 70 mm x 45 mm

- Number of Specimens 6 (Standard)

- Click to view more

X

FLEXOMETER Tester Product Specifications

- To measure the flexing resistance of soles, leathers, rubber products

- Standard Universal Clamp

- Instantaneous on flex

- 75 mm

- Digital/Counter

- Flexometer Tester

- Sturdy construction, easy specimen fixing, precise stroke adjustment

- Push-button/Digital Counter

- Ambient

- 25 mm

- Approximately 70 kg

- 1 cycle

- 1 cycle

- 220V AC, 50 Hz

- 100 5 cycles/minute

- Digital/Manual

- 0 - 100,000 cycles

- 220V AC

- 10C to 35C

- 0 to 100,000 flexing cycles

- 50 Hz

- Laboratory

- Benchtop

- Multiple test stations

- 6 (Standard)

- 70 mm x 45 mm

- Semi-Automatic

- < 65 dB

- Fractional HP electric motor

- 22.5° ± 2°

- Digital non-resettable counter

- Mild steel outer body, powder coated finish

- Specimen clamp set, operation manual, calibration certificate

- IS, ASTM, DIN

- Indoor, dust-free

- Emergency stop switch

- Blue/Silver

Product Description

Presenting the FLEXOMETER Tester with Cycle Counter-a top-drawer solution for evaluating flexing resistance in soles, leather, and rubber products. Equipped with a fractionally powered drive motor and an enviable digital non-resettable counter, this tester brings rarefied precision to laboratory testing. Its mild steel, powder-coated body and emergency stop switch ensures top-tier safety and durability. Offering seamless promotion and monitoring with a 22.5 flexing angle, instant response time, and cycle accuracy, it supports extensive application with multiple test stations. Compliance with premier IS, ASTM, DIN standards makes it the enviable choice for high-end laboratories and factories.

Top Advantages and Applications of FLEXOMETER Tester

The FLEXOMETER Tester's rarefied design suits not only footwear but also leather goods and rubberized products. Key competitive advantages include top-drawer durability, easy specimen fixing, and precise adjustment features. Its enviable multi-station capacity maximizes productivity in plant environments, making it ideal for routine sample checks, quality control, and advanced research settings. Its powder-coated finish and robust construction guarantee reliability and long-term operation in laboratory conditions.

Export Reach, Supply Strength, and Payment Convenience

FLEXOMETER Tester commands enviable outlay in top export markets across Europe, Asia, and the Americas. With efficient logistics, rapid supply ability, and streamlined domestic mar distribution, the product targets importers, exporters, and manufacturers alike. Payment terms are designed for convenience, supporting advance and standard transaction methods. The benchtop mounting and semi-automatic automation further ease procurement and installation, making it attractive for both domestic and international clients.

Top Advantages and Applications of FLEXOMETER Tester

The FLEXOMETER Tester's rarefied design suits not only footwear but also leather goods and rubberized products. Key competitive advantages include top-drawer durability, easy specimen fixing, and precise adjustment features. Its enviable multi-station capacity maximizes productivity in plant environments, making it ideal for routine sample checks, quality control, and advanced research settings. Its powder-coated finish and robust construction guarantee reliability and long-term operation in laboratory conditions.

Export Reach, Supply Strength, and Payment Convenience

FLEXOMETER Tester commands enviable outlay in top export markets across Europe, Asia, and the Americas. With efficient logistics, rapid supply ability, and streamlined domestic mar distribution, the product targets importers, exporters, and manufacturers alike. Payment terms are designed for convenience, supporting advance and standard transaction methods. The benchtop mounting and semi-automatic automation further ease procurement and installation, making it attractive for both domestic and international clients.

FAQ's of FLEXOMETER Tester:

Q: How does the FLEXOMETER Tester benefit laboratory testing processes?

A: It offers precise and instant cycle monitoring, reliable repeatability, and easy specimen fixing, enhancing workflow efficiency and data accuracy for quality control and research.Q: What safety features does the FLEXOMETER Tester include?

A: The unit provides a top-tier emergency stop switch, powder-coated body for durability, and operates at a noise level below 65 dB for safe laboratory environments.Q: Where can the FLEXOMETER Tester be applied?

A: This device is ideal for laboratory, plant quality control, footwear, rubber, and leather product testing-whenever measuring flex resistance is required indoors in dust-proof settings.Q: When should the FLEXOMETER Tester be calibrated?

A: Calibration should be performed regularly as advised in the operation manual or upon receiving the calibration certificate to maintain high measuring accuracy and reliability.Q: What is the process for installing and operating the FLEXOMETER Tester?

A: Installation involves benchtop mounting; operation requires connecting to a 220V AC supply, fixing specimens with the clamp set, and adjusting settings via digital or manual controls using the provided manual.Q: How many specimens can be tested at once, and what is their size?

A: The tester accommodates up to 6 standard specimens, each sized at 70 mm x 45 mm, enabling comparative and batch sample analysis.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free