FATIGUE TESTER

Product Details:

- Frequency 15 Hz

- Test Range 0999999 cycles

- Automation Grade Semi-Automatic

- Specimen Size As per standard (e.g., 50x150 mm)

- Port Size Standard

- Application Rubber, Leather, Footwear, Plastic, Textile fatigue testing

- Humidity Up to 85% RH

- Click to view more

X

FATIGUE TESTER Product Specifications

- Push-button/Toggle

- 5C to 40C

- Bench-top

- 10100 Nm

- 220V AC

- 1 cycle

- 450 mm

- Fatigue Tester

- Up to 999999 counts

- Digital Counter

- 1 cycle

- 220V AC, 50Hz

- Sturdy construction, corrosion resistant, programmable cycle setting

- 65 kg (approx)

- Instantaneous

- 75 mm

- Material testing

- 1-2

- 6 bar (if pneumatic)

- Manual/Automatic

- 60-300 cycles/min

- 50 mm

- Rubber, Leather, Footwear, Plastic, Textile fatigue testing

- Up to 85% RH

- Standard

- 0999999 cycles

- 15 Hz

- As per standard (e.g., 50x150 mm)

- Semi-Automatic

- Overload protection, Emergency stop switch

- Conforms to relevant ASTM/ISO standards

- User-selectable

- <70 dB

- Induction motor

- Stainless Steel clamps

- Mild Steel, powder coated

Product Description

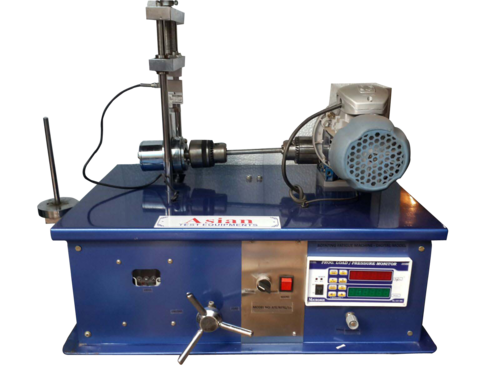

Reserve the elite FATIGUE TESTER-an industry best-seller engineered with matchless precision for fatigue testing in rubber, leather, footwear, plastic, and textile materials. Crafted with a powder-coated mild steel body, stainless steel clamps, and a robust induction motor, this machine ensures instant savings on maintenance with its durable corrosion-resistant construction. Safety is paramount, featuring overload protection and an emergency stop switch. Programmable cycle settings, digital counter, and a user-selectable pre-set deliver control and adaptability, reflecting the very best in advanced material testing technology.

Application Media and Usage: Unrivaled Versatility

The FATIGUE TESTER excels in analyzing material durability for various applications including rubber, leather, plastic, and textiles. Designed for bench-top mounting, it enables reliable testing on flat and flexible surfaces. Whether performing manual or automatic cycles, the device suits the rigorous demands of research labs, quality control, and manufacturing units. Material failure analysis, performance evaluation, and fatigue life determination are simplified, making this device perfect for semi-automatic, high-precision surface testing tasks.

Shipping, Packaging, and Supply Details: Domestic & Export Ready

Dispatched from elite domestic markets, the FATIGUE TESTER is meticulously packaged for damage-free transportation. Standard FOB port options in India ensure prompt shipping, while versatile packaging preserves integrity during transit. Our responsive supply ability adapts smoothly to varying proposal amounts, serving both bulk export and smaller domestic orders efficiently. With robust distribution networks and reliable delivery partners, we ensure every order reaches you safely, maintaining our promise of consistent quality and professional service.

Application Media and Usage: Unrivaled Versatility

The FATIGUE TESTER excels in analyzing material durability for various applications including rubber, leather, plastic, and textiles. Designed for bench-top mounting, it enables reliable testing on flat and flexible surfaces. Whether performing manual or automatic cycles, the device suits the rigorous demands of research labs, quality control, and manufacturing units. Material failure analysis, performance evaluation, and fatigue life determination are simplified, making this device perfect for semi-automatic, high-precision surface testing tasks.

Shipping, Packaging, and Supply Details: Domestic & Export Ready

Dispatched from elite domestic markets, the FATIGUE TESTER is meticulously packaged for damage-free transportation. Standard FOB port options in India ensure prompt shipping, while versatile packaging preserves integrity during transit. Our responsive supply ability adapts smoothly to varying proposal amounts, serving both bulk export and smaller domestic orders efficiently. With robust distribution networks and reliable delivery partners, we ensure every order reaches you safely, maintaining our promise of consistent quality and professional service.

FAQ's of FATIGUE TESTER:

Q: How does the fatigue tester ensure accurate cycle counts during material testing?

A: The fatigue tester incorporates a digital counter with a resolution of 1 cycle and an accuracy of 1 cycle, providing highly precise measurement for every test, and guaranteeing reliable cycle tracking throughout extensive fatigue analysis.Q: What safety features does the fatigue tester offer?

A: This model is equipped with advanced safety provisions including overload protection and an emergency stop switch, helping to mitigate accident risks and protect both the operator and the equipment during tireless testing sessions.Q: Where can the fatigue tester be used within industry sectors?

A: The fatigue tester is suitable for industries such as rubber, leather, footwear, plastics, and textiles, especially in research laboratories, manufacturing facilities, and quality control departments requiring repeatable, accurate fatigue analysis.Q: What is the process for setting test cycles on the machine?

A: Users can pre-set the number of cycles using a programmable interface, allowing selection of up to 999,999 cycles. Control options include both manual and automatic operation, deliver matchless flexibility for diverse testing requirements.Q: When is it beneficial to use the bench-top mounting feature?

A: The bench-top mounting is beneficial when stability and space efficiency are required, allowing operators to securely position the machine in laboratories, ensuring optimal safety and accessibility during frequent testing procedures.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free