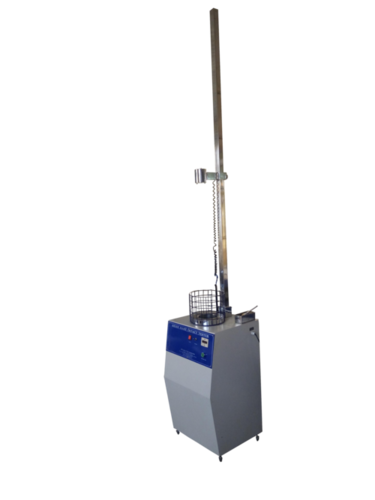

DART IMPACT TESTER

Product Details:

- Frequency 50 Hz

- Interface Type Manual/Push button

- Power Supply 230 V AC, 50 Hz

- Response Time Immediate (physical event-driven)

- Humidity Up to 85% RH (non-condensing)

- Temperature 10C to 40C operating range

- Accuracy 1 g

- Click to view more

X

DART IMPACT TESTER Product Specifications

- Single per test

- Not applicable for metal parts

- Adjustable height, digital readout, robust construction

- Max 2 kg dart (varies with model)

- 10C to 40C operating range

- 1 g

- Laboratory/industrial use

- 0-2000 g

- Up to 300 mm film sample

- Impact strength testing of plastic films, sheets, laminates

- 85 kg

- Variable, up to 2 m

- Immediate (physical event-driven)

- Up to 85% RH (non-condensing)

- 50 Hz

- Manual/Push button

- 230 V AC, 50 Hz

- Semi-automatic

- Free fall (gravity driven)

- 150 mm x 150 mm minimum

- 150 mm diameter clamping ring

- 2000 mm (drop height)

- 50 g to 2000 g (depending on dart size)

- 230 V AC

- Floor standing

- Dart Impact Tester

- Digital/LED panel

- Manual and Digital

- 1 g

- Polyethylene, polypropylene, PVC, laminates, films

- Standard weights set, sample cutter, operation manual

- Stable flat surface, mains power connection

- Graduated scale with lockable position

- Protective enclosure around fall area

- Push button controls with emergency stop

- 38 mm (standard), other sizes optional

- Indoor laboratory use

- ASTM D1709, IS 2508, IS 7016 Pt.4

- Powder coated, anti-corrosive

- Pneumatic/Hand operated

Product Description

- SPECIMEN CLAMP A TWO PIECE ANNULAR SPECIFIED CLAM WITH FACILITY TO VACCUME CLAMPING.

- ELECTROMAGNET FOR SUPPORTING AND RELEASE THE DART ASSEMBLY.

- HEIGHT ADJUSTMENT SYSTEM MEANS TO PROVIDE THE POSITIONING OF THE DART AT SPECIFIED HEIGHT.

- CUSHIONING AND SHIELDING DEVICE TO PROTECT PERSONAL AND TO AVOID DAMAGING THE IMPINGING SURFACE OF DART.

THE INSTRUMENTS IS FINISHED IS METALLIC PAINTING AND BRIGHTCHROME PLATING TO GIVE IT A CORROSION RESISTANT FINISH.

Reliable Impact Testing for Plastic Films

The Dart Impact Tester delivers accurate measurement of impact strength for materials like polyethylene, polypropylene, PVC, and various laminates. With a test width of up to 300 mm and a graduated drop height adjustment, it ensures repeatable, standard-compliant results for both laboratory and industrial applications. The semi-automatic design supports efficient workflows and enhances safety with a protective enclosure.

Adaptable and User-Centric Design

This tester combines robust construction with practical user features, including digital/LED display, push-button controls, and both manual and pneumatic clamping mechanisms. A lockable graduated scale accommodates flexible test heights, while the equipment operates under ambient laboratory conditions. Accessories such as a standard weights set and sample cutter are included for immediate setup and use.

FAQs of DART IMPACT TESTER:

Q: How is the dart impact test conducted using this equipment?

A: The dart impact test is performed by clamping a film specimen in place (using the pneumatic or hand-operated mechanism), selecting the desired dart and drop height (up to 2 meters), and releasing the dart in free fall. The resultant impact is measured to determine the energy needed to cause specimen failure, in accordance with ASTM D1709 and related standards.Q: What materials can be tested with this Dart Impact Tester?

A: This equipment is suitable for testing a range of flexible plastic materials including polyethylene, polypropylene, PVC, plastic films, sheets, and laminates. The specimen must be at least 150 mm x 150 mm in size to fit securely in the 150 mm diameter clamping ring.Q: When should I use the Dart Impact Tester, and what applications benefit from it?

A: Use the Dart Impact Tester when you need to assess the impact strength or resistance of plastic films, sheets, or laminatesespecially in product development, quality control, or certification. It is commonly used by manufacturers, exporters, importers, and quality labs for verifying compliance with global standards.Q: Where should the Dart Impact Tester be installed for optimal performance?

A: Install the tester on a stable, flat laboratory floor near a standard 230 V AC, 50 Hz power source. Ensure the installation site maintains an ambient temperature between 10C and 40C, and relative humidity does not exceed 85% (non-condensing) for best performance and longevity.Q: What is the process for adjusting drop height and ensuring test safety?

A: The drop height can be precisely selected using the graduated scale, which can then be locked to prevent accidental movement. For safety, a protective enclosure surrounds the fall area and the emergency stop button halts operations immediately if required.Q: What are the main benefits of using this Dart Impact Tester?

A: Key benefits include high measurement accuracy (1 g), immediate response to impact events, robust and corrosion-resistant construction, simple operation with digital feedback, and compliance with recognized international standards. This ensures reliable, repeatable results for quality assurance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free