Strength Testing Machine

Product Details:

- Specimen Size 150 mm x 150 mm x 150 mm (typical sample)

- Temperature 5C - 40C

- Humidity Up to 90% RH

- Number of Specimens 1 at a time

- Test Material Cement, Concrete, Bricks

- Port Size Standard

- Test Range 0 - 1000 kgf

- Click to view more

X

Strength Testing Machine Price And Quantity

- 1 Piece

- Microprocessor Based

- Powder Coated

- 150 mm

- Up to 200 mm

- As per IS: 516 / ASTM standards

- Heavy Duty Steel

- Digital / Analog

- 50 Hz

- Sample Holders & Compression Plates

- ±1%

- Overload Protection & Emergency Stop

Strength Testing Machine Product Specifications

- Electric

- 5C - 40C

- Standard

- Mild Steel

- 0 - 1000 kgf

- 800 x 500 x 1400 mm

- Cement, Concrete, Bricks

- 1 at a time

- Compression and Tensile Strength Testing

- Approx. 150 kg

- Industrial

- 150 mm x 150 mm x 150 mm (typical sample)

- Up to 90% RH

- Microprocessor Based

- Powder Coated

- 150 mm

- Up to 200 mm

- As per IS: 516 / ASTM standards

- Heavy Duty Steel

- Digital / Analog

- 50 Hz

- Sample Holders & Compression Plates

- ±1%

- Overload Protection & Emergency Stop

Strength Testing Machine Trade Information

- 10 Piece Per Day

- 5 Days

Product Description

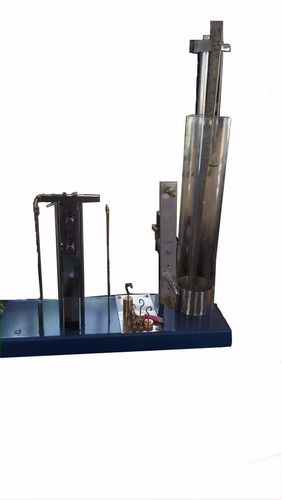

Strength Testing Machine

Our company is known to be one of the top notch manufacturers and exporters of Strength Testing Machine. Precisely engineered using tested quality metals as per industrial standards; these testing machines are appreciated among our clients for their impeccable performance, high operational fluency and long working life. To offer flawless range, we duly test these machines on various quality norms. Strength Testing Machine is primarily used to detect the tensile strength of different kinds of metals and material like plastics, mild steels and ply woods.

Precision Testing for Construction Materials

Equipped with digital or analog displays, this machine offers highly precise strength testing for cement, concrete, and brick materials. Its microprocessor-based system, coupled with automated overload protection, ensures each test is safe, reliable, and conforms to international and Indian calibration standards. The robust construction makes it suitable for rigorous daily industrial use.

Easy Operation and Enhanced Safety

The machines design incorporates a user-friendly interface with rapid emergency stop functionality. Heavy-duty steel framing ensures stability, while overload protection secures both the operator and the specimen during testing. Sample holders and compression plates simplify specimen placement and removal, streamlining the workflow for industrial labs and quality control departments.

FAQs of Strength Testing Machine:

Q: How is the loading accuracy of the strength testing machine maintained?

A: The strength testing machine achieves a loading accuracy of 1% through a microprocessor-based control system. This system continuously monitors the force applied and adjusts in real-time, ensuring precise and consistent results according to calibration standards like IS: 516 and ASTM.Q: What types of materials can be tested using this machine?

A: The machine is designed to test compression and tensile strength in materials such as cement, concrete, and bricks. Its robust build and interchangeable sample holders accommodate typical specimen sizes, making it ideal for a wide range of construction materials.Q: When should the strength testing machine be recalibrated?

A: Regular calibration is recommended as per usage intensity or at least annually. Calibration should be performed as per IS: 516 or ASTM standards to maintain accuracy and comply with quality assurance protocols in industrial environments.Q: Where can this strength testing machine be used?

A: This machine is suitable for industrial applications, particularly in testing laboratories, manufacturing plants, and quality control facilities dealing with construction materials. Its design meets the needs of exporters, importers, and manufacturers across India.Q: What is the operating process for conducting a test?

A: To conduct a test, place the specimen in the designated sample holder, adjust the cross head as required, and set the desired parameters on the digital or analog display. Initiate the test using the microprocessor-based controls. The machine performs the test while its safety features, including overload protection and emergency stop, are active throughout the process.Q: How does the machine benefit industrial users?

A: Industrial users benefit from accurate and consistent strength measurement, essential for quality assurance and meeting regulatory standards. The durable steel frame, safety features, and compliance with global calibration norms enhance productivity and ensure reliable test data for material certification.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free